Punching Outer Ring Needle Bearing

-

(1)illustration for classification and identification

of bearing type

TG-the punching outer ring needle bearing is divided into two series of with-cage (HK,BK) and fullinstalled needle (F,MF,MFH,FY,MFY). The bearings that are conformed to the current standards are ranked for standard type, otherwise ranked for special type.

TG-can provide series punching outer ring needle bearings of non-standard dimension, Nylon cages, of with-labyrinth and high precision (less initial radial gap). Please illustrate your requirements when ordering.

£¨2£©dimension inspection

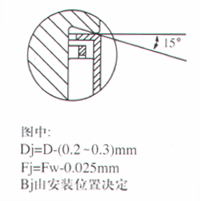

The companies that manufacture the punching outer ring needle bearing all over the world such as Torinton in America, INA in German, NTN and KOYO in Japan regulate definitely that it is non-sense for inspecting its O/D before installation because of the heat-treatment distortion of the thin wall of the punching outer ring. The thin wall punching outer ring gets its final dimensional and geometrical precision after the bearing is pressed into the hole of the base. The dimensional and geometrical precision of the base hole confirm the precision of the inscribed circle of the bearing and the quality of the installed bearing. If the deviation of the dimension of base hole is conformed to the recommended regulation(see Table 6), the diameter of the inscribed circle of the needle will be at the tolerance range of F8 approximately.

Concerning about the correct measurement method of the deviation of the inscribed circle diameter of the needle of the ounching outer ring bearing, the above companies and the national current standards prescribe as follows:

1.The temperature of the measured bearing should be as the same as that of master ring when being measured. The standard measuring temperature is 20¡æ.

2.The inspection of individual minimum I/D deviation(the inscribed circle diameter deviation of the needles) of the group bearing needles is to press the bearing into the hole of the master ring and inspect with the limit plug gauge.

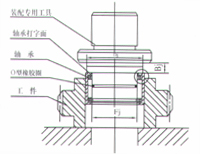

£¨3£©Installation

In order to avoid from partial distortion and fragile crack of punching

outer ring and prevent the bearing from being destroyed at normal running

situation, forbid to knock on the thin wall outer ring with the tooling

such as hammer etc. when installation. Press machine and special tolling

should be used.(following figure)